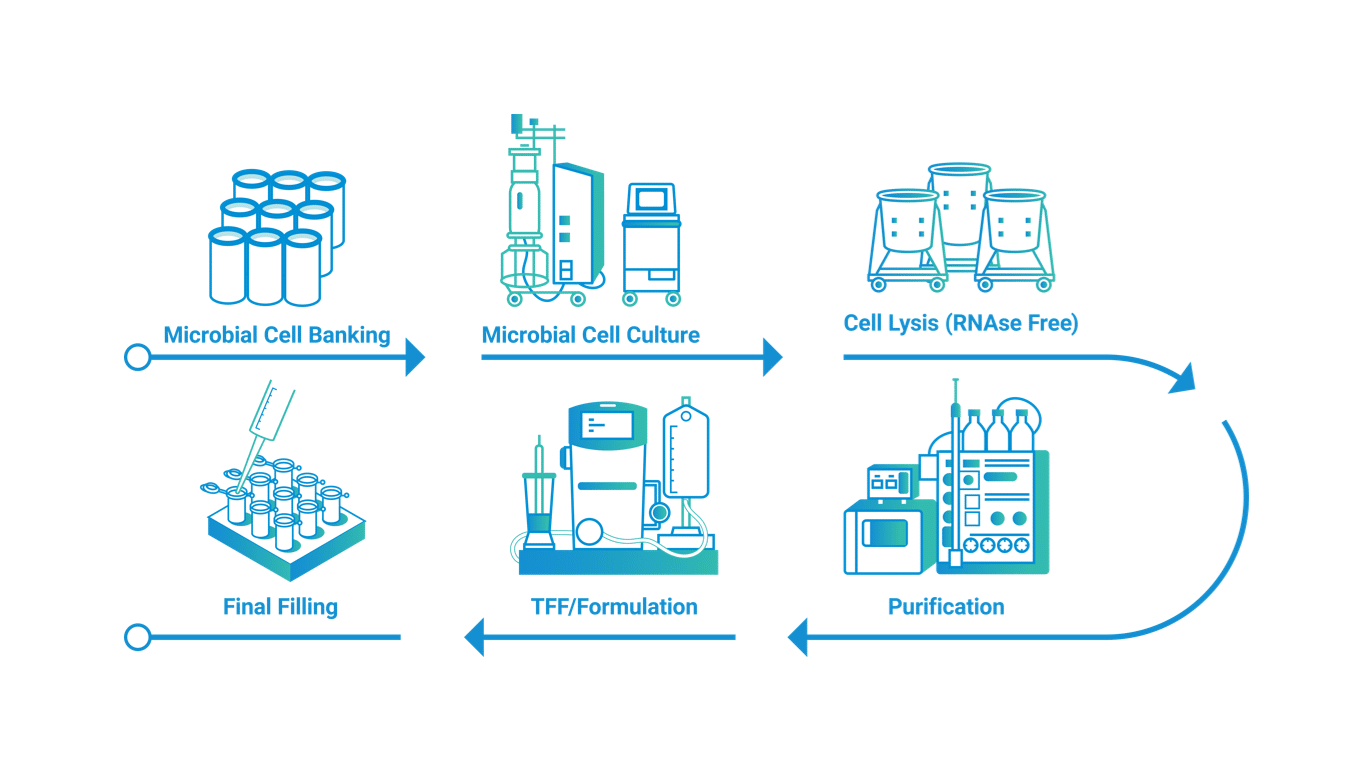

Alkaline Lysis and Clarification

During the manufacturing of plasmid DNA (pDNA), the downstream process begins with the treatment of E. coli biomass, which is generated during the fermentation phase (upstream). This biomass undergoes alkaline lysis, a critical step designed to recover the soluble fraction of pDNA.

Tangential Flow Filtration and Chromatographic Capture

The clarified lysate, containing the pDNA, is further processed using Tangential Flow Filtration (TFF). This technique helps adjust the volume and conductivity of the solution, preparing it for the chromatographic purification steps. The first chromatographic step is crucial for capturing and concentrating the pDNA while eliminating impurities such as host cell proteins, RNAs, and genomic DNA. This is achieved by modulating ion concentrations during the chromatographic process.

Polishing and Purification of Plasmid DNA

In the subsequent purification phase, the plasmid DNA undergoes polishing through Hydrophobic Interaction Chromatography. This step is vital for removing open circular and linear pDNA isoforms, resulting in a product enriched with supercoiled plasmid DNA, which is preferred for therapeutic applications due to its stability and efficiency in gene expression.

Final Concentration and Aseptic Filling

Finally, the purified plasmid DNA is concentrated and filtered in the formulation buffer using TFF. This stage allows customization of the final concentration, formulation buffer, and filling volume according to specific client needs. The final product undergoes sterile filtration and is filled in an aseptic environment into sterile vials, ensuring the highest standards of purity and quality for clinical and commercial applications.